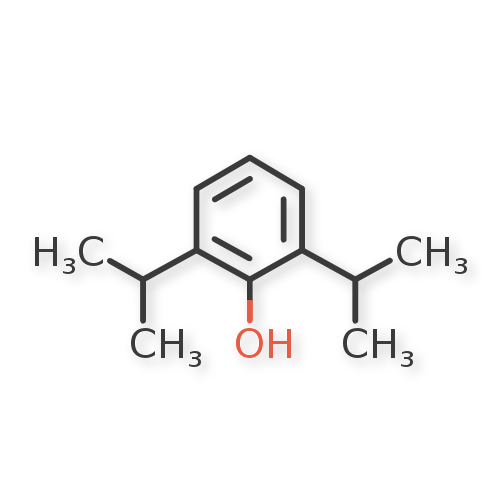

In modern medicine, anesthetic agents play a crucial role in facilitating surgical procedures, with Propofol leading as the most widely used intravenous anesthetic. Often referred to as the "milk of amnesia" due to its milky appearance, Propofol is essential for inducing and maintaining anesthesia. Its fast onset, short duration of action, and predictable pharmacokinetics have made it the preferred choice for surgeries and intensive care. As the UK healthcare sector continues to expand and innovate, the demand for Propofol is rising exponentially. However, ensuring a reliable supply chain of this critical drug presents unique challenges. Pharmaceutical companies must navigate complex regulatory frameworks while maintaining rigorous standards for consistency, sterility, and quality. This is where strategic partnerships with trusted manufacturing entities become indispensable. At Naprod Life Sciences, we bring decades of expertise in pharmaceutical manufacturing to the table, offering EU GMP-certified production facilities and a collaborative approach to contract manufacturing. Although Naprod does not currently supply Propofol directly to the UK market, we are uniquely positioned to partner with UK-based pharmaceutical companies, offering robust solutions that address the rising demand while elevating manufacturing standards.

Naprod’s Expertise in Propofol Manufacturing

1. Regulatory Excellence Manufacturing anesthetic agents like Propofol requires strict adherence to complex regulatory requirements, particularly in highly regulated markets like the UK. Naprod Life Sciences has built its manufacturing capabilities with an unwavering focus on compliance, ensuring that our facilities adhere to both EMA (European Medicines Agency) and MHRA (Medicines and Healthcare products Regulatory Agency) standards.Our EU GMP (Good Manufacturing Practice)-certified facilities operate under stringent quality protocols, covering every step of the manufacturing process, from raw material procurement to final product release. With a comprehensive understanding of international pharmaceutical regulations, Naprod ensures that Propofol formulations meet and exceed the necessary quality benchmarks, making the approval process seamless for our partners.

2. Cutting-Edge Manufacturing Processes The production of Propofol requires precision and advanced technology to maintain the stability and sterility of the formulation. These processes are essential for preserving the chemical integrity of Propofol, ensuring it remains safe and effective throughout its shelf life. Our facilities also utilize automated quality control systems, which incorporate real-time monitoring to minimize contamination risks. This enables Naprod to deliver consistent, high-quality batches of Propofol, catering to the diverse needs of the UK healthcare market.

3. Partnership-Oriented Approach Naprod Life Sciences believes in co-creating value with our partners. Recognizing the unique challenges faced by pharmaceutical companies in regulated markets, we offer tailored solutions that go beyond conventional contract manufacturing. Whether it’s through licensing agreements, co-development initiatives, or bespoke manufacturing solutions, we work closely with our partners to optimize their market offerings. By providing flexibility in production schedules and packaging formats, we ensure that pharmaceutical companies can seamlessly integrate Propofol into their supply chains, meeting the dynamic demands of the UK healthcare system.

Benefits of Partnering with Naprod Life Sciences 1. End-to-End Supply Chain Management At Naprod, we take a holistic approach to supply chain management, ensuring that every aspect of the production and distribution process is handled with precision. From sourcing raw materials to delivering the final product, we provide a seamless and reliable supply chain solution. Our integrated systems reduce lead times and mitigate risks, allowing our partners to focus on expanding their market presence. 2. Scalability for Dynamic Markets The UK healthcare market is characterized by its need for flexibility, catering to both niche specialty drugs and high-demand generics like Propofol. Naprod’s production capabilities are designed for scalability, enabling us to adjust to changing market demands. Whether our partners require small-batch production for clinical trials or large-scale manufacturing for widespread distribution, Naprod has the infrastructure and expertise to deliver. 3. Sustainability Practices As the global pharmaceutical industry moves towards greater environmental responsibility, Naprod is committed to adopting sustainable manufacturing practices. Our facilities are equipped with energy-efficient systems, waste reduction technologies, and environmentally friendly packaging solutions. By aligning our processes with sustainability goals, we help our partners meet corporate social responsibility (CSR) objectives without compromising on quality. A Vision for Collaboration in the UK The growing demand for Propofol in the UK presents a significant opportunity for pharmaceutical companies to expand their portfolios while addressing critical patient needs. However, achieving this requires collaboration with trusted manufacturing partners who can ensure regulatory compliance, production efficiency, and product integrity. Naprod Life Sciences offers a unique proposition for UK-based pharmaceutical companies seeking a reliable Propofol manufacturer. With our EU GMP-compliant facilities, cutting-edge manufacturing processes, and partnership-driven approach, we provide the foundation for successful market entry and sustained growth. While we do not currently operate as direct suppliers in the UK, we are fully equipped to become your strategic partner, offering tailored solutions that empower your brand to meet the evolving needs of the UK healthcare system. Together, we can redefine anesthesia solutions and enhance patient outcomes.